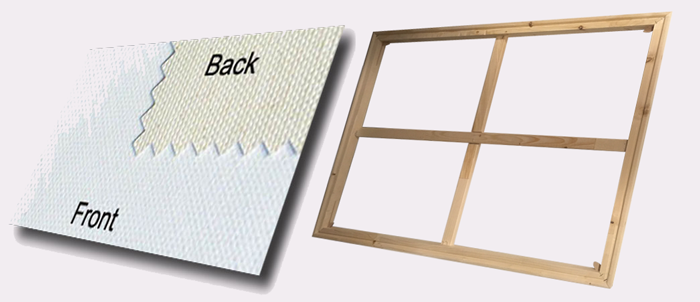

Introduction: Technology has revolutionized various industries, including art. In this article, we discuss how advancements in technology have impacted gallery wrap stretcher bar manufacturing, from precision cutting to automated assembly processes, and the benefits they bring to artists and manufacturers alike.

- Precision Cutting and Machining: Technological advancements have greatly enhanced the precision and accuracy of cutting and machining processes in gallery wrap stretcher bar manufacturing. Computer-controlled machinery, such as CNC routers, allows for precise measurements, angles, and curves, resulting in perfectly shaped stretcher bar components. This level of precision ensures seamless assembly and optimal alignment, contributing to the overall stability and aesthetic appeal of the frame.

- Automated Assembly and Production: Automation has streamlined the assembly and production processes of gallery wrap stretcher bars. Robotic systems can handle tasks like joining, gluing, and fastening components with speed and consistency. Automated assembly lines reduce human error, increase efficiency, and allow for large-scale production. Manufacturers can meet high demand while maintaining quality standards. Additionally, automation enables customization options, as machines can be programmed to produce stretcher bars in various sizes and profiles, catering to specific artistic requirements.

- Digital Design and Prototyping: Digital design software and prototyping techniques have revolutionized the way stretcher bars are developed. Designers can create and visualize stretcher bar prototypes digitally, experimenting with different dimensions, profiles, and joinery techniques before physical production. This digital workflow reduces material waste and accelerates the design iteration process. Additionally, 3D printing technology allows for rapid prototyping of custom connectors, brackets, or accessories, providing greater flexibility and innovation in stretcher bar design.

- Quality Control and Tracking: Technology plays a vital role in ensuring quality control and tracking throughout the manufacturing process. Sensors and imaging systems can detect defects, measure dimensional accuracy, and identify irregularities in the wood or assembly. Quality control software tracks production data, monitoring variables like moisture content, environmental conditions, and production speed. This data-driven approach allows manufacturers to maintain consistent quality standards, identify areas for improvement, and provide traceability for each stretcher bar produced.

Conclusion: Technology has brought significant advancements to gallery wrap stretcher bar manufacturing. Precision cutting and machining, automated assembly, digital design, and quality control systems have elevated the efficiency, accuracy, and customization capabilities in the production process. Embracing technology allows artists and manufacturers to create high-quality stretcher bars that provide sturdy support for artwork while optimizing production and design possibilities.